GESCO Projects and Activities

Maintenance of Ventilation System for Steam Turbine Dormitory at Benghazi Station

completed

General Information

-

Responsible Department :

-

● Power Plants

-

Location:Zouitina

Scope of work

The system consists of six air intake units with air distribution channels inside the house, air exit purifiers from the house, and faults in the system, similar to the faults in the ventilation system in the gas turbine house, with the addition of some keys and contacts missing in the control panels of the systems and the number of three systems whose external building was damaged as a result of its fall from The wind was removed.

The system was electrically isolated and cleaning work began and the damaged parts were removed, as the International Electricity Services Company undertook the maintenance of (3) air intake units for the second double station – north of Benghazi, to reduce the amber temperature to maintain the efficiency of the work of the turbines inside the station, where the air is drawn from outside The house is powered by a fan located in the primary intake unit in which there is a control panel for operating the system and purifiers, and then cold air enters through distribution channels from the fan to the inside of the house.

The air is exited through the purifiers inside the dormitory installed on a wall and distributed over the entire ward in the form of 7 groups, each group containing approximately 32 purifiers.

• Maintenance of the first intake unit (90CJP56EC001))

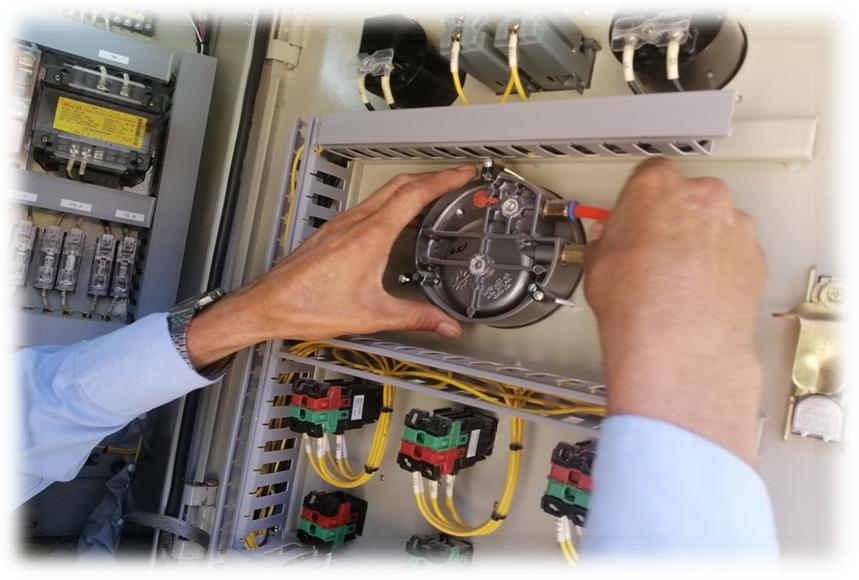

Dust and damaged parts were removed, the air tube was replaced to measure the air pressure difference of the control panel for the first filter, the maintenance of the rotary chain duct for the filter intake of the filter intake motor, the cleaning of the rotary chain from rust and its installation, the replacement of the old first filter with a new one, the dirty parts of the second filter cut and removed and the part returned Clean them, maintain external doors and install lighting for the air intake room.

• Maintenance of the first intake unit (90CJP56EC002))

Dust and damaged parts were removed, the air tube was replaced to measure the air pressure difference of the control panel for the second filter, the maintenance of the rotary chain duct for the filter intake motor the filter motor, and the replacement of the rotary chain, the replacement of the old first filter with a new one, the installation of new filters for the second filter, the maintenance of external doors and the installation of lighting for a room Air pull.

• Maintenance of the first intake unit (90CJP56EC003))

Dust and damaged parts were removed, the air tube was replaced to measure the air pressure difference of the control board for the third cleaner, the control board motor was replaced due to a problem with the coils, and the rotary chain was maintained for the filter pulling out of the filter intake motor, the rotary chain was cleaned of rust and its installation, the old first softener was replaced with a new one, Cut the dirty parts of the second purifier and remove them and return the clean part, maintenance of external doors and installation of lighting for the air intake room.

The maintenance work of the three air intake units has been completed and operated and has been in service since 07/28/2002

1. Maintenance of air purifiers inside the house:

The work of cleaning, filtering, and maintaining the damaged filters and adjusting some tires to get them out of their place, after inspecting them.

Where it was found that the entire purifier inside the ward needs cleaning, as it was the last time it was cleaned for nearly five years, and it was a very long time, and as a result of the previous period, the system was stopped and with the opening of the ward’s doors, the purifier was exposed to dust, which increased the accumulation of dust in it and to increase the efficiency of the work of the system

• Cleaning the entire ward of dust, all oils, and remnants of previous maintenance inside the ward, and closing all doors with daily follow-up of the cleanliness inside the ward to keep the air clean inside the ward.